Imagine a world without stainless steel, a world where your favorite cooking utensils are flimsy and prone to rust. The story of that resilience, that ability to withstand the test of time and the elements, begins with nickel. This fundamental metal, often overlooked, is the unsung hero in countless applications, from the everyday to the extraordinary. But just how much nickel is needed to achieve the desired properties in an alloy? The answer, as you’ll discover, is not a simple one.

Image: brainly.in

Alloying, the art and science of combining metals, is as much about precision as it is chemistry. Every element added impacts the final product in a unique way, and nickel, with its remarkable properties, is a key player in this intricate dance. Today, we delve into the world of nickel alloys, exploring the factors that dictate the amount needed, the impact on material properties, and the applications that make nickel alloys essential in our modern world.

The Nickel Advantage: Why It’s So Important

Nickel is not just another metal. Its unique characteristics put it in a class of its own. Here’s why:

-

Exceptional Strength: Nickel alloys are known for their remarkable strength, far exceeding the capabilities of many other metals. This makes them ideal for applications where high stress and durability are paramount. Think about it – bridges, aerospace parts, and medical implants all require materials that can withstand incredible forces. Nickel delivers.

-

Corrosion Resistance: This is where nickel truly shines. Its inherent resistance to corrosion makes it perfect for environments that would quickly degrade other metals. Imagine a world where your stainless steel cookware quickly rusts, your water pipes corrode, and your industrial equipment quickly degrades. Nickel’s presence in these applications ensures longevity and reliability.

-

Heat Resistance: Nickel alloys can withstand extreme temperatures, making them crucial for heat-sensitive applications. From jet engines to power plants, these alloys function flawlessly in environments where other metals would simply melt or weaken.

-

Magnetic Properties: Nickel’s magnetic properties are equally impressive. They allow for the creation of powerful magnets used in everything from electric motors to hard drives. This magnetic power fuels the technology that drives our modern world.

Determining the Nickel Content: The Art and Science

Determining how much nickel to add to an alloy is not a simple matter of mixing metals. It’s a complex dance involving factors like:

-

Desired Properties: The desired properties of the final alloy drive the nickel content. Do you need greater strength, superior corrosion resistance, or enhanced magnetic properties? Each property requires a specific nickel percentage.

-

Other Alloying Elements: Nickel isn’t always the sole player. Other metals like chromium, iron, copper, and manganese are often incorporated into alloys to achieve specific characteristics. Their presence influences the nickel content needed for a particular application.

-

Manufacturing Processes: The manufacturing process plays a critical role as well. Heat treatments, casting methods, and other production steps can affect the final composition and performance of the alloy.

Understanding the Impact of Nickel Content

The amount of nickel in an alloy directly impacts its properties:

-

Increased Nickel Content: Typically, increasing the percentage of nickel in an alloy enhances its strength, corrosion resistance, and heat resistance. However, this change can sometimes come at the cost of ductility, the ability of a material to deform without fracturing.

-

Decreased Nickel Content: Reducing the nickel content generally decreases the alloy’s strength, corrosion resistance, and heat resistance. However, it can sometimes enhance ductility and lower production costs.

Image: www.chegg.com

Nickel Alloys in Action: A World of Applications

Nickel alloys are found in a wide range of applications, showcasing their versatility and importance in our daily lives:

-

Stainless Steel: This everyday material is a prime example of a nickel alloy. Its corrosion resistance keeps our sinks, cooking utensils, and medical tools shining, while its strength ensures durability.

-

Aerospace: Nickel alloys are essential in aerospace applications due to their high strength, resistance to extreme temperatures, and resistance to fatigue. Think about jet engines, spacecraft parts, and high-performance aircraft components.

-

Power Generation: Nickel alloys are crucial for building power plants, turbines, and other critical infrastructure that provides us with electricity. Their heat resistance and corrosion resistance are vital in high-temperature and corrosive environments.

-

Medical Devices: The biocompatibility of some nickel alloys makes them suitable for medical implants, including prosthetic parts, dental implants, and surgical tools. Their resistance to corrosion and long-lasting strength are essential for maintaining health and well-being.

-

Electronics: Nickel alloys are used in the production of electronics, encompassing everything from batteries to connectors. Their magnetic properties, corrosion resistance, and heat resistance make them crucial components in this rapidly evolving field.

Nickel Alloys: A Sustainable Future

As we move towards a more sustainable future, nickel alloys play a significant role. Their durability ensures long product life, reducing waste and the need for constant replacement. Furthermore, nickel is a recyclable material, minimizing the environmental impact of production and consumption.

Tips for Choosing the Right Nickel Alloy

Choosing the correct nickel alloy involves careful consideration of your application’s specific needs:

-

Identify the Required Properties: Determine the properties needed for your application, such as strength, corrosion resistance, heat resistance, or magnetic properties.

-

Consult with Experts: Connect with metallurgists and engineers to gain insights into choosing the best alloy for your needs.

-

Consider Manufacturing Processes: Think about the manufacturing processes you’ll use and how they might impact the alloy’s final properties.

-

Explore Sustainable Options: Prioritize nickel alloys that are recyclable and minimize their impact on the environment.

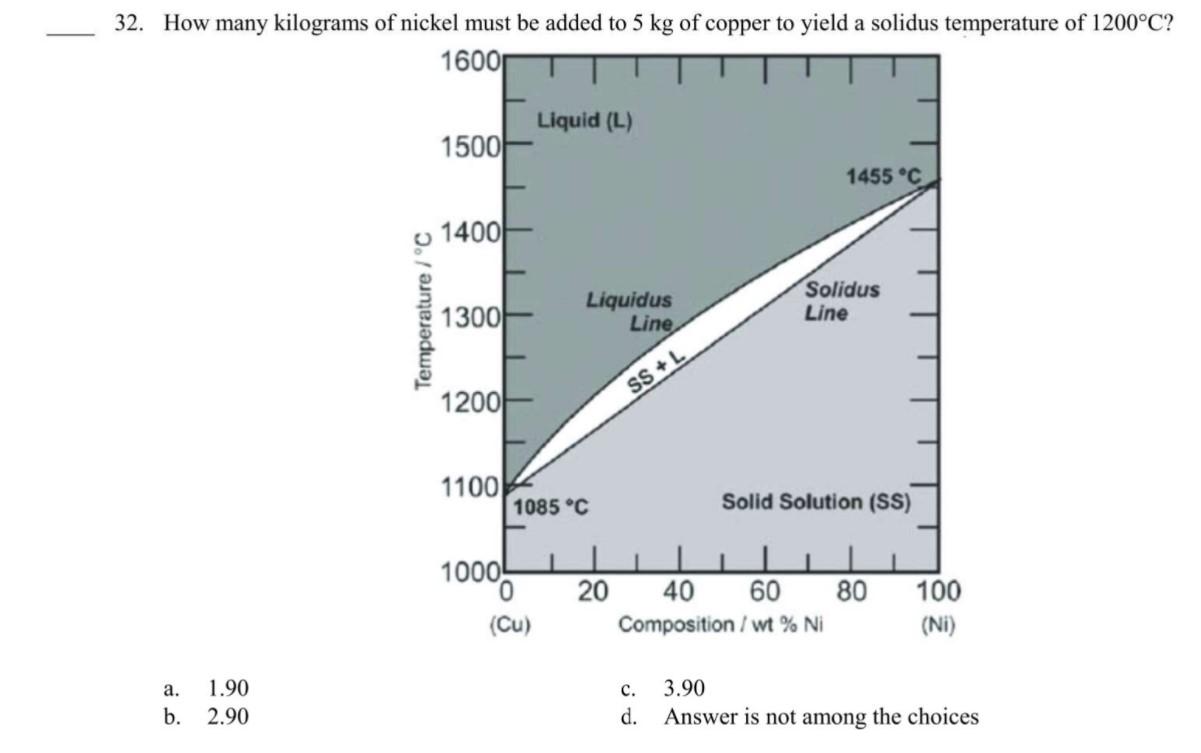

How Many Kilograms Of Nickel Must Be Added To

Conclusion: The Unsung Hero of Modern Materials

Nickel might not be the most glamorous metal, but it’s undoubtedly the unsung hero of our modern world. Its exceptional properties enable a wide range of applications, from daily essentials like stainless steel to advanced technologies like aerospace components.

Understanding how much nickel is needed in an alloy is essential for achieving the desired performance. By considering the factors discussed in this article, you can navigate the world of nickel alloys with confidence. Whether you’re a metal worker, an engineer, or simply someone curious about the materials that shape our world, the story of nickel is one worth exploring. So, next time you see a stainless steel spoon or a gleaming jet engine, remember the silent strength of nickel and its essential role in creating the world we know.